In the BMS (Battery Management System) protection board, resistors are key passive components used in various functional circuits. The following are common types of resistors and their typical application scenarios:

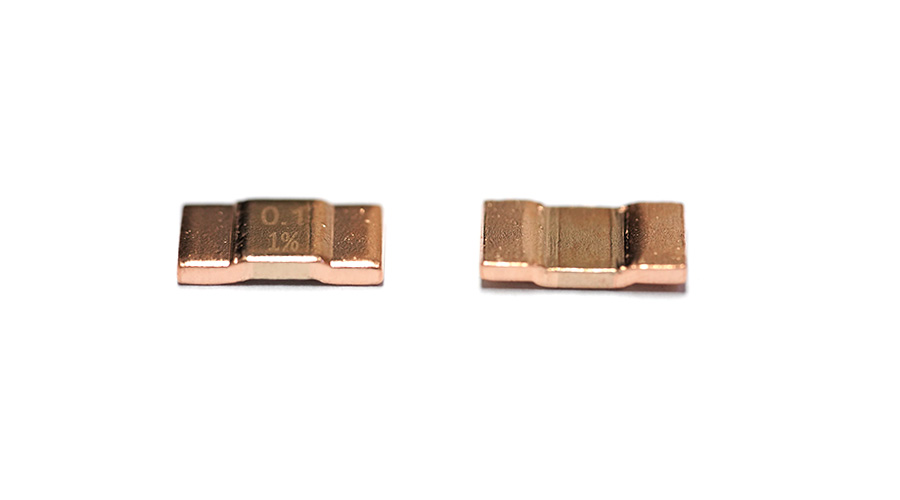

Current detection resistor (Shun Resistor)

Type: Low resistance, high-precision alloy resistors (such as manganese copper, constantan, metal foil resistors).

Parameters: milliohm level (such as 1m Ω~100m Ω), low temperature coefficient (TCR) (within ± 50ppm/℃), accuracy ± 1% or higher.

Function: Connected in series in the battery circuit, calculate the charging and discharging current by measuring the voltage drop (in conjunction with operational amplifiers or dedicated ICs).

Brand examples: Isabellenh ü tte (ISA), Vishay, KOA.

Voltage Divider

Type: Thin film resistor (such as thick film, metal film).

Parameters: High precision (± 0.5%~± 1%), low temperature drift, resistance range usually in the k Ω level (such as 10k Ω~1M Ω).

Function: Used for detecting the voltage of a single battery cell, dividing high voltage to the measurable range of ADC.

Attention: It is necessary to match resistor pairs to reduce voltage division errors.

Pull up/Pull down resistor

Type: Universal thick film resistor.

Parameters: Common resistance value of 1k Ω~10k Ω, accuracy of ± 5%.

effect:

Pull up: Ensure that the signal line defaults to a high level (such as I2C communication, MOSFET driver).

Pull down: prevent signal floating (such as enable pins, reset circuits).

Current limiting resistor

Type: Carbon film or metal film resistor.

Parameter: Select the resistance value according to the load (such as 220 Ω~1k Ω for LED indicator lights).

Function: Limit the driving circuit (such as MOSFET gate LED、 The current of the optocoupler.

NTC thermistor (temperature monitoring)

Type: Negative temperature coefficient thermistor.

Parameters: Commonly used 10k Ω (at 25 ℃), with a B value range of 3000~4000K.

Function: Attach to the battery or PCB to monitor temperature and prevent overheating (requires cooperation with a voltage divider circuit).

Cell Balancing

Type: Power type metal film or wire wound resistor.

Parameters: Resistance value of several Ω~tens of Ω, power of 1W~5W (designed according to balanced current).

Function: Consume excess power in passive balancing circuits to ensure consistent battery pack voltage.

Filter/damping resistor

Type: Thin film or carbon film resistor.

Parameters: Low resistance value (such as 10 Ω~100 Ω), low inductance design.

effect:

Forming an RC filter with capacitors to suppress signal noise (such as voltage detection lines).

Connect in series on the switch signal line to reduce ringing (such as MOSFET gate).

Fusible Resistors

Type: Wire wound or metal film safety resistor.

Parameter: Specific resistance value, will melt when overcurrent occurs.

Function: As a backup protection, it cuts off the circuit in case of abnormalities (such as redundant design of overcurrent protection).

Key considerations for selection

Accuracy: High precision (within ± 0.5%) is required for voltage/current detection, and it can be relaxed for general circuits.

Temperature coefficient (TCR): Maintain stability in high and low temperature environments (such as current detection resistors requiring ± 50ppm/℃ or below).

Power: Choose the appropriate packaging based on the heat generation (such as high-power TO-220 or aluminum shell packaging for balanced resistors).

Reliability: Automotive grade BMS may require AEC-Q200 certified resistors.

By selecting these resistors reasonably, BMS can accurately monitor the battery status (voltage, current, temperature) and achieve protection functions (overcharge, overdischarge, short circuit, balance, etc.).