The BMS (Battery Management System) protection board provides precise protection against physical, electrical, and system level anomalies that may occur during battery operation through multi-dimensional monitoring and intelligent control. The following provides a detailed explanation of the protection mechanism and technical implementation for the eight major categories of anomalies:

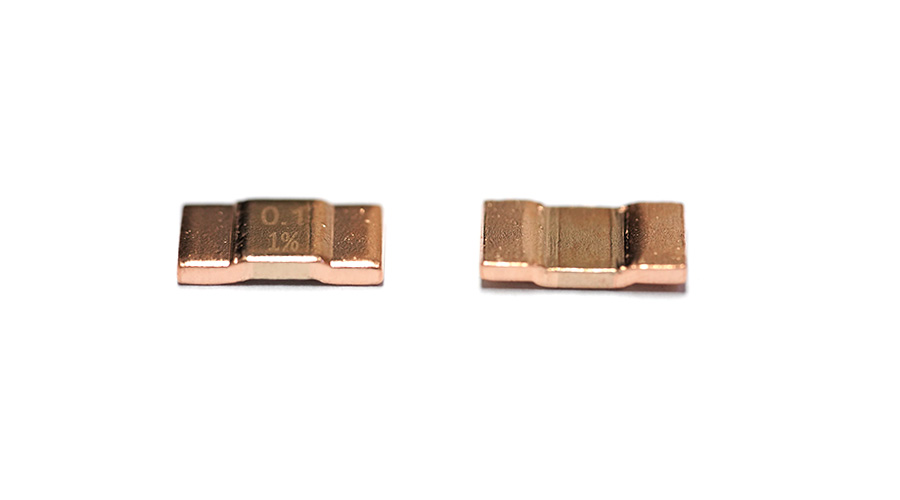

Recommended low resistance shunt resistors for BMS battery protection board: Ellon-ESR series

1、 Voltage abnormality protection

Overvoltage protection

Trigger condition:

Single cell voltage of ternary lithium battery ≥ 4.25V (charging cut-off threshold ± 0.05V);

Lithium iron phosphate battery cell voltage ≥ 3.65V

Protective action:

Cut off the charging MOSFET, trigger the balancing circuit to release voltage, with a response time of less than 50ms

Case: Abnormal communication at the charging station resulted in loss of control during the constant voltage phase, causing the BMS to cut off the circuit within 0.1 seconds.

Undervoltage protection

Trigger condition:

Single cell voltage of ternary lithium battery ≤ 2.7V (with 5% SOC redundancy retained);

Lithium iron phosphate battery cell voltage ≤ 2.0V

Protective action:

Graded power reduction output (50% → 30% → 0%) to avoid electrode damage caused by deep discharge.

2、 Abnormal current protection

Overcurrent protection

Trigger threshold:

Continuous current>1.5 times the rated value (such as 150A set for 100A system), instantaneous pulse current>3 times (lasting for 10ms).

Protective action:

Adopting IGBT/MOSFET hard turn off and synchronously recording fault logs (such as Tesla BMS recording overcurrent times for quality assurance analysis).

Short circuit protection

Detection mechanism:

When the current change rate is greater than 1000A/s, the hardware comparator directly triggers protection with a response time of ≤ 10 μ s.

Layered protection:

The first level protection turns off the MOS, and the second level protection melts the fuse, completely physically isolating the fault point.

3、 Temperature anomaly protection

High temperature protection

Graded response:

Level 1 (55 ℃): 50% reduction in output power;

Level 2 (65 ℃): Start the liquid cooling pump to forcibly dissipate heat;

Level 3 (80 ℃): Power off and activate the thermal runaway suppression system (such as spraying fire extinguishing agent).

Low temperature protection

Charging restrictions:

-Charging is prohibited below 10 ℃, and the discharge circuit is cut off at -20 ℃ to prevent lithium metal precipitation.

Heating strategy:

Automatically start PTC film heating in low temperature environment, with a heating rate controlled at 1 ℃/min.

4、 Battery consistency anomaly protection

Voltage imbalance

Passive equilibrium trigger: Single cell pressure difference>50mV (ternary lithium)/80mV (iron lithium), equilibrium current 100mA

Active balancing optimization: When the pressure difference is greater than 30mV, energy transfer is initiated with an efficiency greater than 85%.

Internal resistance imbalance

Testing technology:

By measuring the AC internal resistance through EIS (electrochemical impedance spectroscopy), a deviation greater than 15% is marked as a degraded cell;

Dynamic adjustment:

Limit the depth of charge and discharge of abnormal individual cells (such as narrowing the SOC usage range to 20% -80%).

5、 Communication and system fault protection

Bus communication interruption

Redundant switching:

When the CAN bus is lost for more than 500ms, switch to the daisy chain backup channel to ensure data continuity;

Maintaining safety status:

When communication is completely interrupted, enter the preset safe mode according to the last valid command.

Data verification exception

Error correction mechanism:

CRC check error triggers data retransmission, and if there are three consecutive errors, the communication module will be restarted;

Black box function:

Store the last 1000 fault records (including timestamps and operating parameters), and support UDS protocol reading.

6、 Mechanical and environmental anomaly protection

Collision and impact protection

Acceleration sensor:

Detected>10g instantaneous impact (equivalent to 30km/h collision), disconnect the high-voltage circuit within 0.5 seconds;

Activation of pressure relief valve:

When the internal pressure of the box exceeds 20kPa, it automatically opens to prevent the risk of explosion.

Environmental adaptability protection

High altitude compensation:

When the altitude is greater than 3000 meters, the relay contact voltage increases by 0.2V to counteract the effect of thin air;

Moisture proof treatment:

Start internal heating and dehumidification in environments with humidity>90%, and maintain relative humidity<60%.

7、 Abnormal protection for charging device interaction

Abnormal output of charging station

Voltage fluctuation protection:

Detected charging voltage exceeding the nominal value by ± 10% (e.g. nominal 400V system>440V), refused charging handshake;

Pulse interference suppression:

Eliminate high-frequency noise greater than 100kHz through EMC filters to ensure sampling accuracy.

Protocol mismatch

Multi protocol compatibility:

Automatically identify charging standards such as GB/T, CCS, CHAdeMO, etc., and suspend charging when the protocol version difference exceeds 2 generations.

8、 Software logic exception protection

State machine error

Dual MCU verification:

The master-slave controller synchronizes status information every 200ms, and if the difference persists for more than 3 cycles, a system reset is executed;

Watchdog mechanism:

Software heartbeat packet timeout>1 second triggers hardware reset to prevent program from running away.

OTA upgrade risk

Secure Boot:

When firmware signature verification fails, roll back to the previous stable version to ensure system reliability.

Extension of cutting-edge protection technology

AI predictive protection:

Based on LSTM algorithm, predict the risk of overvoltage/overheating in the next five minutes, and adjust the working mode in advance;

Digital twin simulation:

Build a virtual model of the battery, simulate the failure path under extreme working conditions, and optimize the protection threshold setting.

The abnormal protection system of BMS protection board has evolved from single parameter monitoring to multi-dimensional collaborative intelligent security network. Today, as the energy density of power batteries exceeds 300Wh/kg, their protection response speed (such as short-circuit protection<10 μ s) and decision accuracy (voltage detection ± 1mV) continue to break industry standards. In the future, with the application of solid-state batteries and lithium metal anodes, BMS will face more complex interface side reaction monitoring requirements, promoting the evolution of protection technology towards atomic level sensing and quantum computing diagnosis.