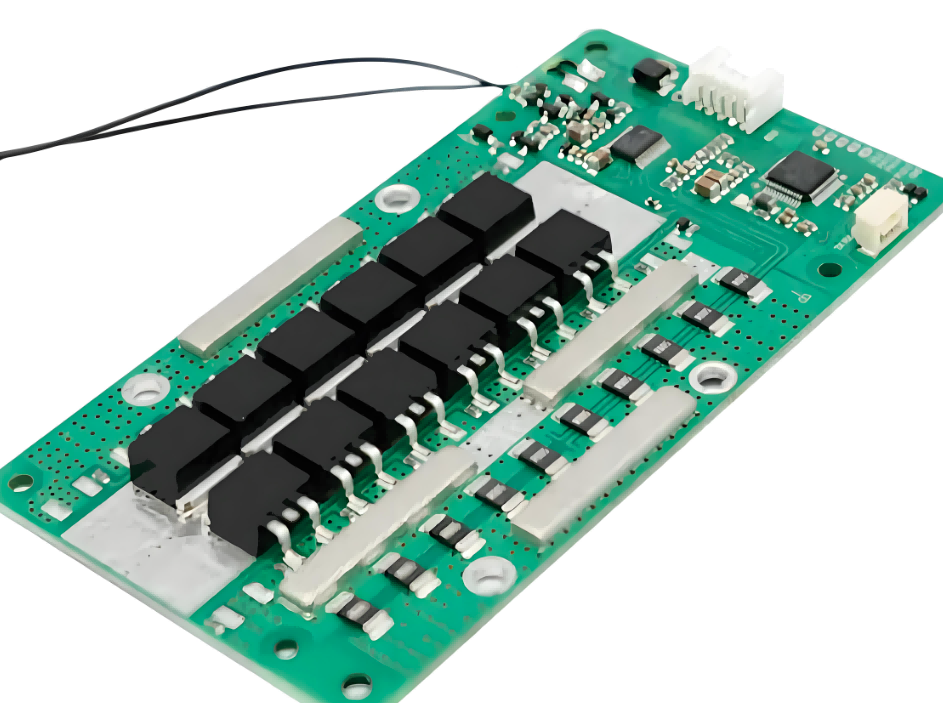

The BMS battery protection board (battery management system protection board) serves as the intelligent control center of the battery pack, undertaking multiple functions from basic protection to advanced management. Its functional design is closely centered around the three core goals of battery safety, performance optimization, and system integration. The following is a detailed explanation of the core functions of the BMS battery protection board:

Recommended alloy resistors for BMS battery protection board: Yineng EMA series

1、 Basic protection function: Building a battery safety defense line

The BMS battery protection board establishes a multi-level safety protection mechanism through the coordinated control of hardware and software

Voltage protection

Overcharge protection: Real time monitoring of individual cell voltage, cutting off the charging circuit when the ternary lithium battery exceeds 4.25V or the lithium iron phosphate battery exceeds 3.65V to prevent electrolyte decomposition from causing thermal runaway.

Overdischarge protection: When the individual voltage is below 2.5V (ternary lithium) or 2.0V (lithium iron phosphate), it is forced to shut down to avoid permanent capacity loss caused by copper foil dissolution.

Current protection

Overcurrent protection: The current is detected by a Hall sensor, and the power battery pack is usually set with a trigger threshold of 1.53 times the rated current, with a response time of less than 20ms

Short circuit protection: The hardware circuit can identify a short circuit and disconnect the MOSFET within 10 μ s, and the software algorithm locks the fault state after secondary confirmation.

Temperature protection

Monitor the surface temperature of the battery cell and the ambient temperature, with a working range typically set between 20 ℃ and 60 ℃. When the temperature exceeds 55 ℃ or the temperature difference between the battery cells is greater than 8 ℃, power limit or forced cooling will be activated.

2、 State monitoring and management: achieving precise energy control

The BMS battery protection board constructs a digital image of the battery through high-precision sensors and advanced algorithms

Real time parameter collection

The voltage detection accuracy reaches ± 1mV (such as TI BQ76952 chip), the current sampling error is less than 0.5%, and the temperature monitoring resolution is 0.1 ℃.

Critical state estimation

SOC (State of Charge): Combined with ampere hour integration method, open circuit voltage method, and Kalman filtering algorithm, the accuracy can reach ± 3% (required for electric vehicle grade).

State of Health (SOH): Calculated using the internal resistance growth rate and capacity decay model, with an error controlled within ± 5%.

Power boundary prediction

Based on battery temperature, SOC, and aging degree, dynamically calculate the maximum charge and discharge power (SOP) to ensure performance and safety in high load scenarios.

3、 Balanced management: solving the problem of battery consistency

The BMS battery protection board improves the overall efficiency of the battery pack through balancing technology:

Passive equilibrium

Using resistance energy dissipation method, the balanced current is usually 50200mA, which is low-cost but only 60% -70% efficient, suitable for small capacity scenarios such as electric tools.

Active equilibrium

By using inductors/capacitors to achieve energy transfer, the balanced current can reach 15A, and the efficiency can be improved to over 90%. The Tesla Model 3 adopts distributed active balancing, with individual voltage differences controlled within 10mV.

4、 Communication and System Interaction: Building an Intelligent IoT Network

The BMS battery protection board serves as an information hub to achieve multi-dimensional data exchange:

Internal communication

Isolation CAN or daisy chain communication is used between the master control unit (BMU) and the slave control unit (CMU) to ensure the coordinated operation of multiple modules.

External protocol docking

Supports industrial protocols such as CAN 2.0B, RS485, Modbus, etc., for real-time interaction with vehicle control units (VCUs) or energy storage EMS systems.

High end models integrate Bluetooth/WiFi modules, allowing users to check battery health through a mobile app (such as BYD Blade Battery Management System).

5、 Fault diagnosis and warning: proactive risk prevention and control

BMS battery protection board built-in intelligent diagnostic system:

Real time fault detection

Identify hidden faults such as micro short circuits and contactor adhesion, with a diagnostic coverage rate of over 98% (compliant with ISO 26262 ASILC standard).

Warning and Data Recording

Store the last 1000 fault logs and support UDS protocol reading. The thermal runaway warning system can issue an alarm 15 minutes in advance (according to the requirements of GB 380312020).

6、 Scenario based extension function: Empowering diverse applications

Based on the needs of different fields, BMS battery protection boards have derived special functions:

Fast charging management

In the 4C supercharging scenario, dynamically adjust the charging curve and monitor the risk of lithium deposition (such as CATL Kirin Battery BMS).

Low temperature adaptability

-Automatically start PTC heating at 30 ℃ environment to ensure lithium ion migration rate and increase charging efficiency by 40%.

Tiered utilization support

Energy storage retired battery BMS can reset SOC/SOH parameters and adapt to secondary use scenarios.

Technological Evolution and Future Functions

With the development of technology, BMS battery protection boards are integrating AI and cloud platforms:

Digital twin: Building a virtual model of the battery to achieve life prediction and maintenance planning;

Edge computing: Localized operation of neural network algorithm improves the accuracy of fault identification to 99.5%;

OTA upgrade: Remote update protection strategy, such as NIO optimizing charging temperature threshold through FOTA.

The functional design of BMS battery protection board always seeks performance breakthroughs within the safety red line. From basic voltage protection to AI driven predictive maintenance, its role has evolved from a "passive defender" to an "active manager". Today, with the penetration rate of new energy vehicles exceeding 30%, the technological iteration of BMS battery protection boards will continue to drive the evolution of energy storage systems towards safer and more efficient directions.