High Voltage Capacitor is a capacitor designed specifically for high voltage environments, with a rated voltage typically ranging from several hundred volts to tens of thousands of volts, or even higher. This type of capacitor is optimized for high electric field strength, insulation performance, and voltage stability in terms of structure, materials, and processes, and is widely used in the fields of energy, industry, healthcare, and scientific research. The following is a detailed analysis of high-voltage capacitors:

Core characteristics of high-voltage capacitors

High voltage withstand capability: With a wide rated voltage range (commonly 200V~100kV+), it can withstand instantaneous or continuous high voltage.

Low loss: The dielectric material has low dielectric loss (tan δ), reducing energy waste and heat generation.

Strong insulation: using special structures and materials to prevent breakdown (such as multi-layer series connection, vacuum packaging).

Anti arc design: suppresses discharge or corona effect between electrodes under high voltage.

Temperature stability: able to withstand high or low temperature environments (such as 40 ℃~150 ℃).

Main types and structures

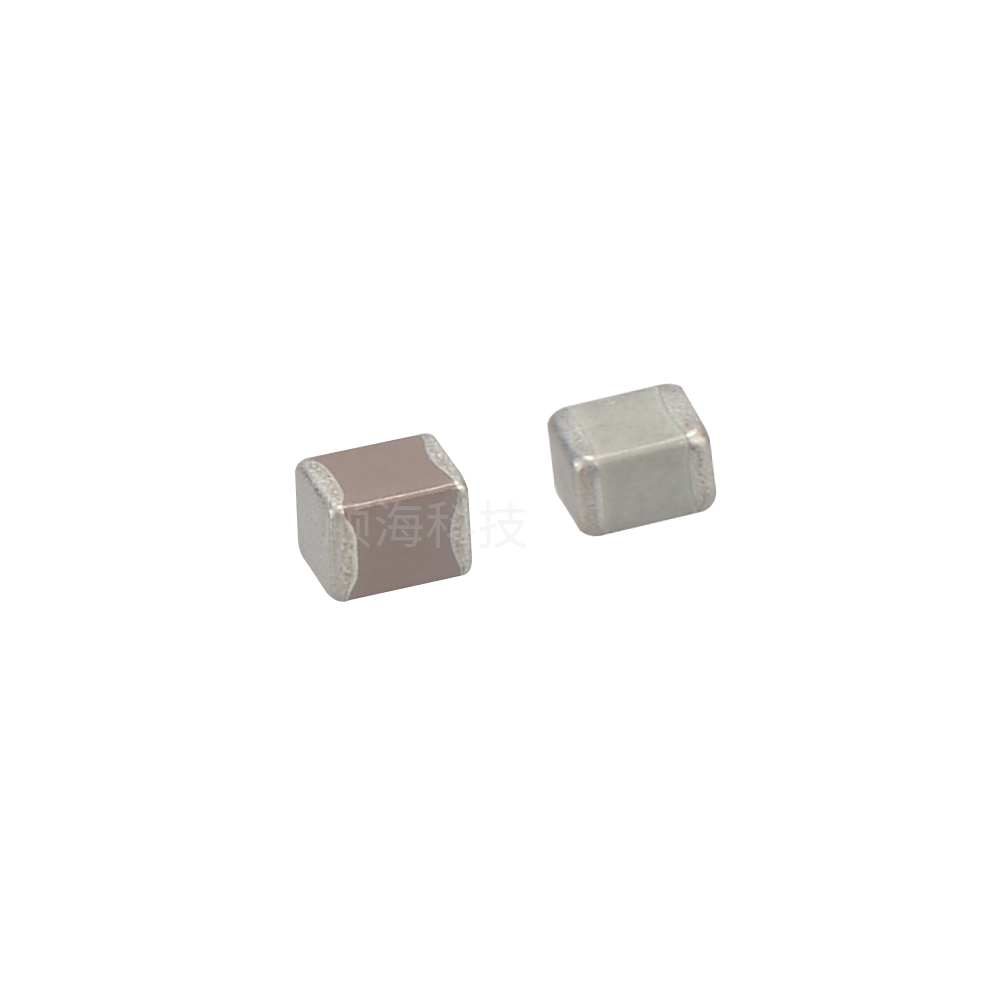

(1) Ceramic high-voltage capacitor

Dielectric material: a type of ceramic (such as C0G/NP0) or high-voltage specific ceramic (strontium titanate based).

Structure: Multi layer ceramic stack (MLCC) or single-layer disc type, with silver plated electrodes on the surface.

Characteristics:

Capacity range: 1pF~0.1 μ F (smaller capacity under high pressure).

Excellent high-frequency performance and extremely low ESR.

The withstand voltage can reach 10kV~50kV.

Application: RF transmitter, Tesla coil, high-voltage power resonant circuit.

(2) Thin film high-voltage capacitor

Media materials: polypropylene (PP), polyester (PET), polytetrafluoroethylene (PTFE).

Structure: Metallized film winding, electrodes made of aluminum foil or zinc aluminum evaporation layer.

Characteristics:

Capacity range: 0.001 μ F~100 μ F.

Strong self-healing ability (automatic repair after local breakdown).

Wide voltage withstand range (1kV~100kV).

Applications: Switching power supply, X-ray machine, laser pulse power supply.

(3) Electrolytic high-voltage capacitor

Type: Aluminum electrolysis or solid-state electrolysis.

Structure: Multiple electrolytic paper layers, filled with liquid or solid electrolyte.

Characteristics:

Large capacity (1 μ F~10mF), but relatively large volume.

Voltage resistance is usually<600V (aluminum electrolysis) or<1000V (solid state).

The lifespan is greatly affected by high temperatures.

Application: DCLink energy storage for frequency converters and inverters.

(4) Oil immersed/gas insulated high-voltage capacitor

Medium: insulating oil (mineral oil, silicone oil) or sulfur hexafluoride (SF ₆) gas.

Structure: The metal electrode is immersed in an insulating medium, and the shell is sealed and explosion-proof.

Characteristics:

Ultra high voltage withstand (up to 500kV+), large capacity.

Strong arc resistance and good heat dissipation performance.

Large size and extremely high cost.

Applications: power systems (such as capacitive voltage transformers), particle accelerators.

Typical application scenarios

Energy and electricity:

Power transmission: reactive power compensation, harmonic filtering (such as high-voltage parallel capacitor compensation devices).

New energy: DC support capacitors for photovoltaic inverters and wind power converters.

Industrial equipment:

Inverter: energy storage and filtering (such as elevator and rolling mill drive systems).

Welding equipment: Energy storage capacitors provide instantaneous high-voltage pulses.

Medical equipment:

X-ray machine: pulse capacitor in high-voltage generator (20kV~150kV).

MRI: High voltage filtering of gradient coil drive circuit.

Research and Military Industry:

Particle accelerator: Pulse Forming Network (PFN) capacitor (100kV~1MV).

Electromagnetic cannon: high-energy pulse discharge capacitor group.

Consumer Electronics:

Camera flash: A small high-voltage capacitor (300V~1000V) stores energy.

Key parameters for selection

|Parameter | Description|

|Rated voltage | Actual operating voltage should be ≤ 80% of the rated value (e.g. 1000V capacitor used for ≤ 800V circuit). |

|Capacity stability | Capacity may decrease under high voltage (especially for thin film/ceramic capacitors), please refer to the voltage capacity curve. |

|ESR/ESL | Low ESR is required for high-frequency scenarios (such as selecting ceramic capacitors for RF circuits and thin film capacitors for pulse circuits). |

|Temperature coefficient | Choose C0G ceramic or PTFE film capacitors for high temperature environments to avoid capacity drift. |

|Life and reliability | Electrolytic capacitors have a shorter lifespan, while oil immersed/solid-state capacitors are more suitable for long-term high-voltage operation. |

|Packaging form | Surface mount (low power), bolt type (high power), or sleeve type (ultra-high voltage). |

Precautions for use

Security protection:

High voltage capacitors may still store charges after power failure, and residual electrical energy needs to be released through discharge resistors or specialized tools.

Wear insulated gloves during operation to avoid electric shock.

Installation spacing:

Maintain sufficient creepage distance on the PCB (e.g. ≥ 8mm for 1kV) to prevent arc discharge.

Environmental control:

Avoid damp and dusty environments to prevent a decrease in insulation performance.

Series/Parallel:

Series connection requires balancing the voltage distribution with a voltage equalizing resistor; Parallel connection requires consideration of current sharing and heat dissipation.

High voltage capacitor vs. ordinary capacitor

|Comparison item | High voltage capacitor | Ordinary capacitor|

|Rated voltage | Usually ≥ 200V, up to one million volts level | Generally<100V (such as 6.3V~50V for surface mount ceramic capacitors)|

|Dielectric materials | Polypropylene, C0G ceramics, insulating oil, etc. | Aluminum electrolyte, X7R ceramics, ordinary film|

|Insulation design | Multi layer insulation, anti corona coating, vacuum packaging | Single layer medium, no special protection|

|Volume and weight | Larger (especially oil immersed/gas insulated) | Compact (such as 0603 surface mount capacitors only in millimeters)|

|Cost | High (complex materials and processes) | Low (suitable for mass use in consumer electronics)|

High voltage capacitors are the core components of high-voltage and high-energy storage scenarios, and their design emphasizes voltage resistance, insulation, and reliability. When selecting, it is necessary to comprehensively consider the voltage level, frequency characteristics, environmental conditions, and cost, especially in power systems, medical equipment, and scientific research instruments, where the performance of high-voltage capacitors directly determines system safety and efficiency. When using, it is necessary to follow safety regulations to avoid accidents caused by improper design or operation.