Battery Management System: The Core Guardian of Energy Storage

The Battery Management System (BMS) is the core control unit of modern battery packs, and its importance is becoming increasingly prominent with the popularization of new energy technologies. As an intelligent hub connecting battery hardware and application scenarios, BMS ensures the efficient and safe operation of the battery system through real-time monitoring, optimized control, and safety protection.

1、 Core functions of battery management system

The battery management system integrates sensors, controllers, and algorithms to achieve full lifecycle management of battery packs. The specific functions can be divided into four modules:

1. Status monitoring and evaluation

BMS real-time collects parameters such as battery voltage, current, temperature, etc., and accurately estimates the state of charge (SOC), state of health (SOH), and power state (SOP) of the battery through Coulomb counting, equivalent circuit modeling (ECM), or machine learning algorithms. For example, in electric vehicles, SOC accuracy can reach ± 3%, ensuring the reliability of range prediction.

2. Balanced management

In response to the performance differences between battery cells, BMS adopts passive balancing (resistance energy dissipation) or active balancing (energy transfer) technology to control the voltage difference between cells within 10mV, avoiding the "barrel effect" that leads to a decrease in overall capacity.

3. Thermal management

By using liquid cooling, air cooling, or phase change materials, BMS maintains the temperature of the battery pack within the optimal range of 15-35 ℃. Research has shown that for every 10 ℃ increase in temperature, the degradation rate of lithium battery life will double, and precise temperature control can extend battery life by more than 30%.

4. Fault diagnosis and protection

BMS is equipped with multi-level protection mechanisms such as overvoltage, undervoltage, overcurrent, and short circuit, with a response time of less than 100ms, which can effectively prevent thermal runaway accidents. For example, Tesla BMS can cut off the faulty circuit within 0.1 seconds, significantly improving safety.

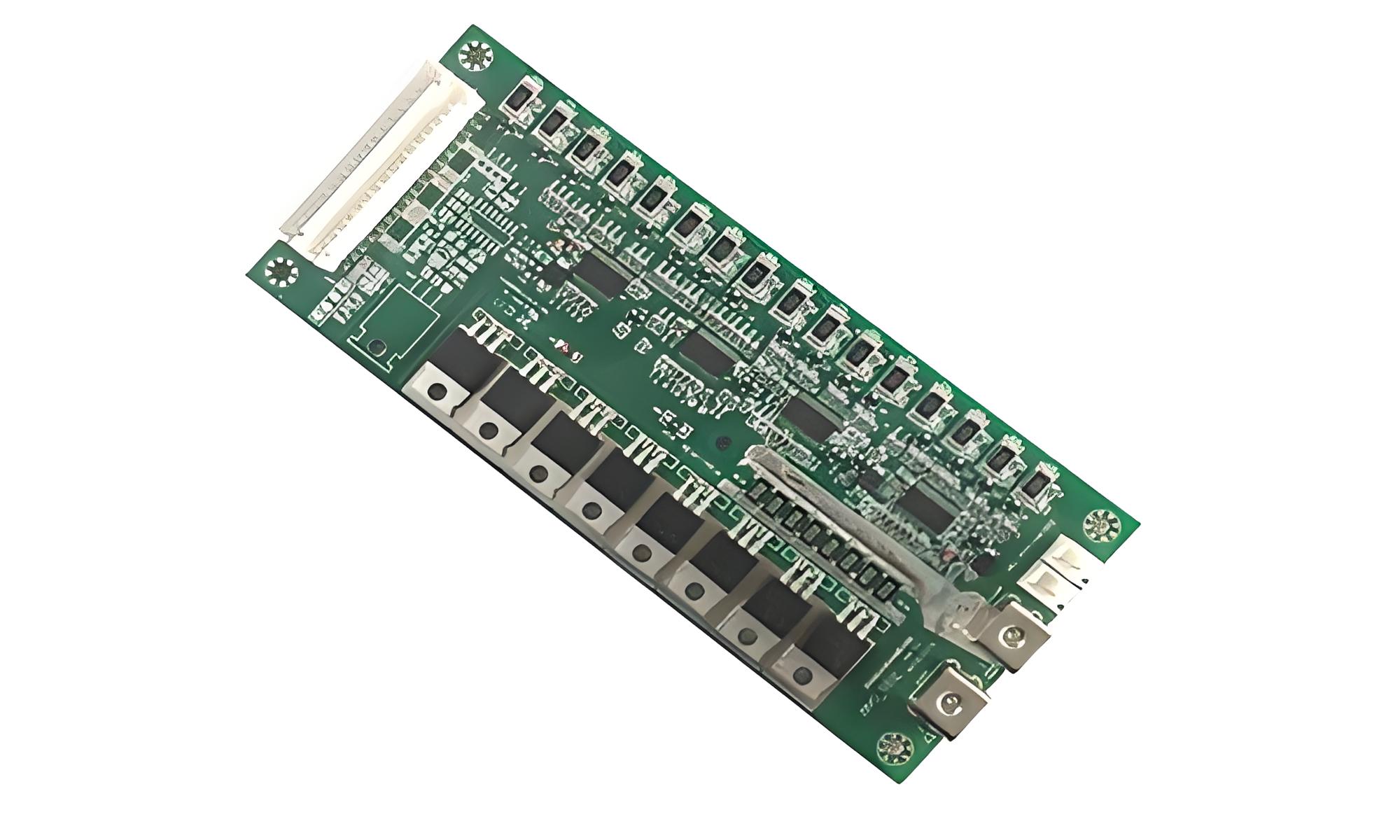

2、 Hardware architecture of battery management system

A typical BMS adopts a layered distributed design, which includes the following hardware units:

Main control module (BMU): As the decision-making center, equipped with 32-bit MCU chips (such as NXP S32K series), responsible for data integration and instruction issuance.

Control Module (CMU): Each module manages 6-24 battery cells and is equipped with high-precision AFE chips (such as TI BQ76PL536) to achieve μ V level voltage detection.

Communication interface: Supports CAN bus, RS485 or wireless Bluetooth transmission, seamlessly interfaces with vehicle control unit (VCU) or energy storage system.

Execution unit: including relays, fuses, and cooling pumps, directly executing system instructions.

3、 Technological breakthroughs in software algorithms

The intelligence level of modern BMS highly relies on algorithm innovation:

Adaptive filtering algorithm: combining Kalman filtering and ampere hour integration method to dynamically correct SOC estimation errors.

Digital twin model: Simulate the aging process through battery digital mirroring to achieve life prediction and maintenance warning.

Edge computing optimization: deploy lightweight AI models on local processors to reduce cloud dependency and improve response speed.

4、 Application scenarios of battery management system

1. Electric vehicles

BMS is the "brain" of electric vehicles, directly affecting range, charging speed, and safety. For example, CATL Kirin batteries use BMS to achieve 4C fast charging technology, which can recharge 400 kilometers in 10 minutes.

2. Energy storage power station

In grid level energy storage, BMS needs to manage tens of thousands of batteries, support peak valley frequency regulation and black start functions, and the system cycle efficiency can reach over 92%.

3. Consumer electronics

Mobile phones, drones, and other devices use miniature BMS chips (such as MAX17320) to achieve charge and discharge protection and optimize battery life.

5、 Key technological challenges and development trends

The current BMS is facing three major challenges: insufficient state estimation accuracy under multi parameter coupling, real-time bottleneck of large-scale systems, and the challenge of global climate adaptability. Future development directions include:

Chip level integration: Embed BMS functions into the battery pack, reducing wiring harness costs by 30%.

Cloud edge collaboration: Combining 5G and cloud computing to achieve remote diagnosis and OTA upgrade of battery clusters.

Safety redundancy design: Introducing functional safety level ASIL-D certification to meet ISO 26262 standards.

conclusion

As a cornerstone technology of the new energy revolution, battery management systems are evolving from a single controller to an intelligent energy management platform. With the breakthrough of new materials such as solid-state batteries and sodium ion batteries, BMS needs to continuously innovate algorithm architectures and cross domain fusion capabilities to provide underlying technical support for carbon neutrality goals. In the future, the next generation BMS with self-learning and self-healing capabilities may redefine the boundaries of energy storage.