As a bridge for connecting devices for data transmission and charging, USB data cables not only involve basic conductor materials, but also contain various key electronic components to achieve functional optimization and safety assurance. The following are common electronic components and their functions in USB data cables:

Conductors and shielding materials

Copper core conductor: used for transmitting current and data signals, usually made of oxygen free copper (purity above 99.99%) to reduce resistance and heat generation, and improve conductivity efficiency.

Aluminum foil shielding layer: wrapped around the outer layer of the conductor, mainly used for electromagnetic shielding to prevent external interference signals from affecting the quality of data transmission.

Braided mesh shielding layer: further enhancing anti-interference ability, some high-end wires adopt multi-layer shielding structure (such as six layer shielding) to cope with complex electromagnetic environments.

Protective components

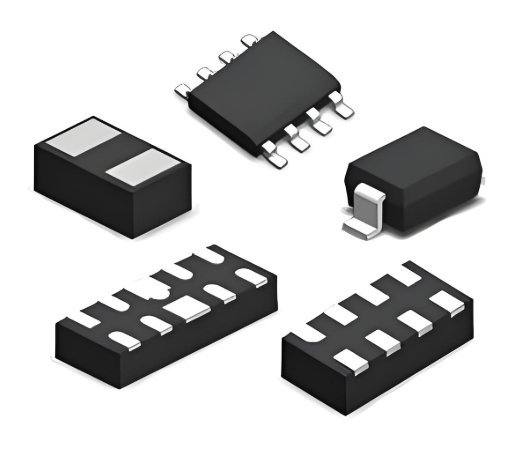

ESD (electrostatic discharge) protection devices:

Deep retrace ESD: such as Hunan Jingxin's SEUCS2X24V1B, used for CC/SBU pin protection of USB 4.0 interface, with ultra-low clamp voltage (5.6V) and extremely low capacitance (0.12pF), to avoid damage to sensitive circuits caused by electrostatic discharge.

TVS (Transient Voltage Suppressor): such as the ESD73411Z from Hawei Group, used for USB 3.2/4.0 high-speed signal line protection, with fast response speed and can suppress surges and electrostatic shocks.

Surge Suppressor (TDS): such as Hunan Jingxin's ESTVS2200DRVR, used for VBUS pin protection, supports 20V~36V working voltage, and prevents voltage transients during high-power charging.

Protocol and Power Management Chip

E-Marker chip: embedded in USB-C cables, used to identify cable specifications (such as power, data transfer rate) and negotiate fast charging protocols (such as USB PD 3.1) with devices to ensure safety and compatibility.

PD controller: In cables that support USB Power Delivery (PD), this chip manages the dynamic adjustment of voltage and current (such as supporting 5A current, 48V high voltage), achieving power transmission of up to 240W.

Intelligent diversion chip: integrated into a multi in one data cable, automatically distributes power to different devices to avoid overload or efficiency decline.

High speed signal transmission related components

Differential signal protection devices, such as deep flyback ESD devices (SEUCS2X3V1B), are used to protect USB 4.0 ultra high speed differential signal lines (such as Tx/Rx channels), ensuring signal integrity at transmission rates of 40Gbps~80Gbps.

Optoelectronic conversion module: In long-distance fiber optic USB cables, laser and driver chips (such as King Kable's fiber optic cables) need to be integrated to convert electrical signals into optical signals to reduce attenuation and interference.

Interface and connector components

Type-C interface chip: integrates CC logic control function, manages interface direction detection, role switching (host/device), and power supply strategy.

Overvoltage protection switch: such as ADI's ADIMAX20334, protects data lines from high voltage short circuits and surges, supports ± 15kV ESD protection and -30V~+45V surge suppression.

Other auxiliary components

Flame retardant material: The high-end cable sheath is made of nylon weaving or liquid silicone, which has passed flame retardant certification (such as 3C certification) to enhance safety.

Magnetic module: Some magnetic data cables have built-in magnetic connectors to enhance convenience and durability.

The selection of electronic components for USB data cables is closely related to their functional positioning:

Basic cables: mainly consisting of conductors, shielding layers, and simple protective devices.

Fast charging/high-power cable: requires integration of E-Marker chip, PD controller, and high-voltage protection device.

High speed/long-distance cables: relying on ESD protection, optoelectronic conversion modules, and differential signal optimization design.

Multi in one smart cable: combining protocol chips and intelligent distribution technology to achieve multi-functional compatibility.

For more detailed technical parameters or application scenarios, please refer to the product descriptions of relevant manufacturers (such as Infineon, Shuokai, Hawei Group, etc.).