Okay, rectifier diodes, as a key electronic component specifically used to convert alternating current (AC) to direct current (DC), have the following significant characteristics that make them play an irreplaceable role in the field of power conversion:

Core function: Unidirectional conductivity

This is the fundamental property of all diodes, and more importantly, the core foundation of rectifier diodes. It only allows current to pass relatively easily in one direction (forward, from anode to cathode), while in the opposite direction (reverse) it exhibits extremely high resistance, almost blocking the current. This characteristic is the fundamental principle for achieving "rectification" (turning alternating current into unidirectional current).

Design focus: High current processing capability

Different from low-power diodes used in signal processing, one of the core design goals of rectifier diodes is to carry a larger forward current. Power circuits, such as power adapters, chargers, and industrial equipment power supplies, typically require substantial power supply, which means that the current flowing through rectifier diodes may reach amperes (A) or even higher levels. Therefore, the chip area, wire bonding, and packaging of rectifier diodes are specially designed to dissipate heat and withstand these currents.

Key parameters: high reverse withstand voltage

In rectification applications, diodes need to withstand the negative half cycle (reverse voltage) peak of the AC input voltage. This peak voltage may be much higher than the effective value (RMS) of the AC voltage. For example, the peak value of 220V AC power is approximately 311V. Therefore, rectifier diodes must have a sufficiently high reverse breakdown voltage (commonly known as PIV Peak Inverse Voltage or VRRM Repetitive Peak Reverse Voltage) to ensure that avalanche breakdown does not occur and damage them during reverse bias. The common voltage withstand range of rectifier diodes varies from tens of volts to thousands of volts.

Efficiency consideration: forward conduction voltage drop

When the rectifier diode is conducting in the forward direction, there will be an inherent voltage drop (VF - Forward Voltage Drop) at both ends. For standard silicon rectifier diodes, this voltage drop is usually around 0.7V to 1.1V (depending on the current size and model). Although this voltage drop is necessary (as a result of forming a PN junction barrier), it will result in power loss (loss power=VF IF). In high current applications, this loss cannot be ignored and is an important factor affecting power efficiency. Schottky rectifier diodes have lower forward voltage drop (usually between 0.3V-0.6V), making them particularly suitable for low voltage and high current applications to improve efficiency.

Speed characteristics: relatively slow switching speed

Standard rectifier diodes (such as the common 1N400x series and 1N540x series) are based on silicon PN junctions. When they switch from forward conduction to reverse cutoff state, they require a period of time to "clear" the minority carriers stored inside the PN junction, which is called the reverse recovery time. This time is relatively long (usually in the microsecond range).

Impact: The longer reverse recovery time limits its application in high-frequency switching circuits (such as the primary side of modern switching power supplies), as high-speed switching can generate significant reverse recovery current spikes and switching losses, reducing efficiency and potentially causing electromagnetic interference. For high-frequency applications, fast recovery diodes or Schottky diodes (the latter having almost no minority carrier storage effect and extremely fast reverse recovery) are required.

Structural foundation: Based on PN junction

The vast majority of standard rectifier diodes use PN junctions formed from silicon materials as their core structure. Its performance (such as withstand voltage, current capacity, voltage drop) mainly depends on the design, manufacturing process, and material characteristics of the PN junction. Schottky rectifier diodes utilize the Schottky barrier formed by metal semiconductor contacts and have different physical mechanisms.

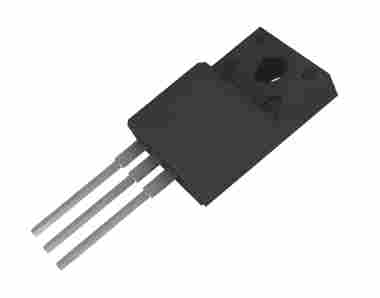

Packaging form: sturdy and durable

In order to adapt to carrying high currents and possible high temperature environments, rectifier diodes are usually packaged in sturdy and durable materials. Common forms include:

Axial lead packaging: such as DO-41 (1N400x series), DO-201AD (1N540x series). Small size, low cost, suitable for medium power.

Bolt installation and packaging: such as TO-220AB, TO-247. Equipped with a metal backplate or built-in heat sink mounting holes, it is easy to install onto the heat sink and suitable for high-power applications.

Surface mount packaging: such as SMA, SMB, SMC, DPAK. Adapting to the needs of miniaturization and automated mounting of modern electronic devices, the power capacity varies.

Application oriented: Reliability and Cost

Rectifiers typically operate at critical locations in power circuits, and their reliability is crucial. They need to be able to withstand startup surge currents, voltage fluctuations, and long-term high-temperature operation.

For widely used standard models such as 1N4007 and 1N5408, low cost is another important feature, which makes them widely used in various consumer electronics and industrial equipment. Of course, the cost of high-performance or special types of rectifier diodes (such as ultra fast recovery, high voltage, high current) will correspondingly increase.

In summary, the core characteristic of rectifier diodes is to utilize their unidirectional conductivity and optimize their design to safely and reliably handle the large forward currents and withstand high reverse voltages required in power conversion. At the same time, their inherent conduction voltage drop and switching speed characteristics are key factors to consider when selecting and applying them. These characteristics make it an indispensable basic component for building various DC power systems.