Deep analysis of alloy resistance and sampling resistance

In electronic circuit design, alloy resistors and sampling resistors are two core components with significant differences in functional positioning, material properties, and application scenarios. The following analysis will be conducted from three dimensions: technical essence, performance parameters, and application fields:

1、 Core definition and functional differences

Alloy resistance: Material driven current carrier

Technical essence: Using special alloy materials (such as manganese copper, constantan, nickel chromium alloy) as conductive media, optimizing material ratios to achieve low resistance, high power, and high stability.

Core functions:

Current detection: Using low resistance characteristics (usually in the milliohm range) to convert current into measurable voltage signals.

Current limiting protection: prevents circuit overload through high power bearing capacity (such as 2512 packaged alloy resistors with a power of up to 3W).

Signal transmission: As an impedance matching component in high-frequency circuits, it reduces signal reflection.

Sampling resistor: a function oriented signal converter

Technical essence: A broad classification of resistors, whose core value lies in converting current/voltage signals into collectable analog quantities.

Core functions:

Current sampling: Connected in series in the circuit, the current value is calculated by measuring the voltage at both ends (such as monitoring battery charging and discharging current in electric vehicle BMS system).

Voltage sampling: parallel connected in the circuit, divided and supplied to ADC (Analog to Digital Converter) for processing.

Feedback control: Adjust the output voltage stability through sampling resistors in a switching power supply.

2、 Comparison of Material Characteristics and Performance

Characteristic Parameters: Alloy Resistance, Sampling Resistance

Material system: manganese copper alloy, constantan alloy, nickel chromium alloy, Kama alloy, manganese copper alloy, constantan alloy, nickel copper alloy, ceramic alloy

Resistance range 0.2m Ω~600m Ω (mainstream) 0.0001 Ω~1 Ω (mainly milliohm level)

Power withstand 1W~5W (1206 package) 0.33W~10W (2512 package)

Temperature coefficient 25ppm~100ppm (low drift) ± 5ppm~± 50ppm (ultra-low drift)

Accuracy level 1%, 0.5% (conventional) 0.01% (precision level)

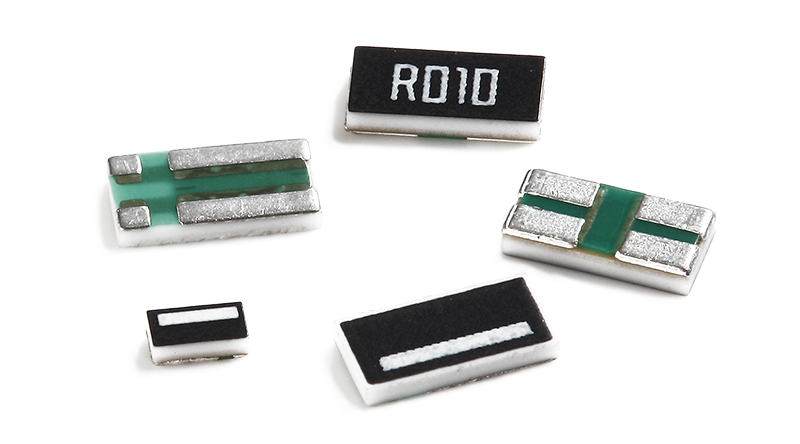

Package size 0402~4527 (including miniaturization 0201) 0201~2728 (suitable for portable devices)

Key Differences:

Alloy resistors emphasize the conductivity and thermal stability of the material itself (such as Kama alloy's temperature resistance of up to 300 ℃), while sampling resistors focus on achieving ultra-low temperature coefficients through material optimization (such as ± 5ppm grade products).

Sampling resistors need to meet a precision requirement of 0.01% in precision applications, while alloy resistors are more concerned with resistance stability in power scenarios.

3、 Application scenarios and selection logic

Typical Applications of Alloy Resistors

High current scenario:

Electric vehicle battery management system (BMS): monitors the charging and discharging current of the battery pack (such as 2512 packaged 0.5m Ω alloy resistor).

Industrial frequency converter: As a shunt, it can withstand hundreds of amperes of current.

High frequency circuit:

5G communication equipment: Match impedance to reduce signal loss.

Extreme environment:

Aerospace equipment: Kama alloy resistors work stably at -55 ℃~150 ℃.

Typical Applications of Sampling Resistors

Precision power management:

Laptop charging circuit: Control the charging current accuracy through a 0.001 Ω sampling resistor.

Feedback control system:

LED driver: Sampling resistor feedback voltage to stabilize output current.

Portable devices:

Smart watch: 0201 packaging sampling resistor achieves efficient use of space.

Selection suggestion:

Alloy resistance: Prioritize choosing manganese copper alloy (low resistance range) or iron chromium aluminum alloy (high resistance range), and pay attention to matching power and temperature coefficient.

Sampling resistor: Select 0.01% grade products according to accuracy requirements, and prioritize 0201/0402 packaging for portable devices.

4、 Technology Trends and Market Landscape

Material Innovation:

Alloy resistance: Ceramic alloy materials break through the bottleneck of miniaturization (such as resistance values below 0.001R).

Sampling resistor: The nanoscale thin film process achieves ultra-low resistance (0.0001 Ω) and high precision.

Deepening industry applications:

Alloy resistors: There is a surge in demand in the fields of new energy (photovoltaic inverters) and automotive electronics (OBC car chargers).

Sampling resistor: With the popularity of Type-C fast charging, high-power sampling resistors (such as 3W/5W) have become standard.

Conclusion: The essential difference between alloy resistors and sampling resistors is that the former is driven by materials science and focuses on high current and extreme environmental applications; The latter is guided by functional requirements and serves precision measurement and control. In practical selection, it is necessary to make a comprehensive decision based on circuit topology, environmental conditions, and cost objectives.