Analysis of the Six Core Characteristics of Metal Foil Resistors

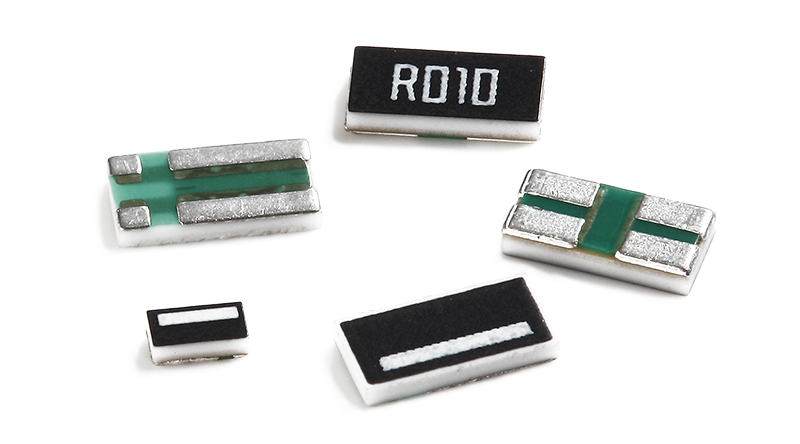

As a core component in the field of precision electronic components, metal foil resistors occupy an important position in high-end industrial equipment, medical instruments, and aerospace industries due to their unique manufacturing processes and material characteristics. This article systematically elaborates on its six key characteristics from the perspectives of materials science and engineering applications.

1、 Temperature stability (TCR < ± 2ppm/℃)

The temperature coefficient (TCR) of the resistor manufactured by ion etching process using micrometer sized alloy foil can be controlled within ± 2ppm/℃. This characteristic originates from the unique electron mobility stability of alloy materials, such as a resistance change amplitude of less than 0.02% in a wide temperature range of 55 ℃ to+125 ℃, providing reliable temperature compensation for crystal oscillator circuits and precision measurement equipment.

2、 Ultra low noise characteristics (<40dB)

The continuous lattice structure of metal foil effectively suppresses electron scattering noise, and in applications such as audio amplifiers and high-sensitivity sensors, its current noise level is reduced by three orders of magnitude compared to traditional winding resistors. Through scanning electron microscopy observation, it can be seen that the surface roughness of the foil material is controlled at Ra<0.1 μ m, effectively reducing contact noise.

3、 High frequency response characteristics (parasitic inductance<0.08 μ H)

The unique planar structure endows metal foil resistors with excellent high-frequency characteristics. In GHz level RF circuits, their equivalent series inductance (ESL) is 60% lower than that of thin film resistors. Experimental data shows that using metal foil resistors in power amplifiers for 5G communication modules can reduce signal distortion to below 0.003%.

4、 Long term stability (annual drift<0.005%)

The alloy foil treated by vacuum annealing process showed a resistance change rate of less than 50ppm in the accelerated aging test at 85 ℃/85% RH for 1000 hours. This characteristic enables it to have a service life of over 25 years in scenarios that require long-term stable operation, such as satellite navigation systems and nuclear magnetic resonance equipment.

5、 Power density characteristics (surface load>1.5W/cm ²)

The specially designed heat dissipation structure enables the power density of metal foil resistors to reach more than three times that of traditional surface mount resistors. In the current sharing circuit of the electric vehicle charging module, its transient power bearing capacity can reach 10 times the rated power, and it can work continuously for more than 5000 hours without performance degradation.

6、 Mechanical stress resistance characteristics (vibration>20g)

The metal foil resistor packaged with elastic epoxy resin technology can withstand a random vibration test with an acceleration of 20g under MILSTD202G standard. Practical application has shown that in the traction system of high-speed trains, its resistance to mechanical impact is 8 times higher than that of ordinary resistors, and the failure rate is reduced to the level of 0.1 ppm.

Application scenario extension

These characteristics make metal foil resistors irreplaceable in the following fields:

Medical equipment: CT scanner high voltage generator

Aerospace: Inertial Navigation System

New energy: MPPT circuit for photovoltaic inverters

Intelligent car: autonomous driving LiDAR

Through continuous material innovation (such as adding rare earth elements to improve temperature characteristics) and process improvement (laser fine-tuning accuracy up to 0.01%), metal foil resistors are moving towards greater precision (0.001% tolerance), miniaturization (0201 packaging), and intelligence (built-in temperature sensing), continuously driving electronic technology innovation.