Gas discharge tube is a device that uses the principle of gas discharge for overvoltage protection, widely used in communication, power, security and other fields. Its core function is to quickly conduct when overvoltage occurs, clamp the voltage within a safe range, and protect subsequent circuits. The following is a detailed classification and technical analysis of gas discharge tubes:

1、 Classified by structural type

Diode type gas discharge tube

Structure: Two electrodes are sealed in a ceramic or glass tube and filled with inert gas (such as neon or argon).

Features: Bidirectional symmetrical protection, suitable for AC or DC circuits.

Application: Power lightning arrester, signal lightning arrester.

Triode type gas discharge tube

Structure: Three electrodes (two main electrodes and one trigger electrode), which can achieve lower breakdown voltage.

Features: Faster response time, suitable for high-frequency signal protection.

Application: Communication base station, high-frequency induction heating equipment.

2、 Classification by gas type

Air discharge tube

Gas: Air.

Characteristics: Low cost, but poor breakdown voltage stability.

Application: Low voltage distribution system, security monitoring.

Inert gas discharge tube

Gases: Neon (Ne), Argon (Ar), Xenon (Xe), etc.

Characteristics: Stable breakdown voltage and long lifespan.

Applications: Precision instruments, communication equipment, aerospace.

3、 Classified by purpose type

Gas discharge tube for power lightning protection

Function: Suppress lightning induced overvoltage on power lines.

Parameters: current capacity (10kA~100kA), response time (<100ns).

Application: Switching power supply, LED driver, industrial equipment.

Gas discharge tube for signal lightning protection

Function: Protect high-speed signal interfaces (such as RS-485, CAN bus) from ESD/surge interference.

Parameters: Low capacitance (<1pF), low insertion loss.

Applications: Communication equipment, industrial control, automotive electronics.

Gas discharge tube for lightning protection of antenna feeder

Function: Absorb lightning induced pulses on the antenna feeder.

Parameters: High power processing capability (10kW~100kW), wideband (DC~6GHz).

Applications: base stations, broadcasting and television transmission stations, radar systems.

4、 Classified by packaging form

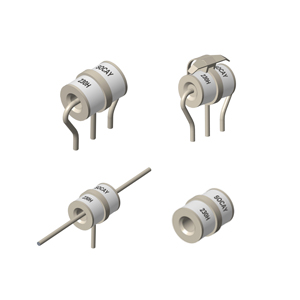

Plug in gas discharge tube

Packaging: Radial leads (such as φ 5mm, φ 10mm), axial leads.

Application: high-power power supply, industrial control cabinet.

Advantages: Good heat dissipation performance, suitable for high current scenarios.

Surface mounted gas discharge tube

Packaging: SMD packaging (such as 1206, 1812).

Application: Portable devices, high-density PCBs.

Advantages: Small size, suitable for automated mounting.

Special packaged gas discharge tube

Example: Gas discharge tube with heat sink (for high-power scenarios), waterproof packaging (for outdoor applications).

5、 Typical application scenarios

Communication base station

Example: Antenna feeder lightning arrester, power supply lightning arrester.

Selection: Transistor type gas discharge tube with a current capacity of 50kA~100kA.

Industrial control

Examples: PLC, frequency converter, servo drive.

Selection: Diode type gas discharge tube with a current capacity of 10kA~20kA.

Automotive Electronics

Example: ECU, car charger, ADAS sensor.

Selection: Surface mounted gas discharge tube, certified by AEC-Q200, high temperature resistance (-55 ℃~+150 ℃).

Security monitoring

Example: Camera, network switch, access control system.

Selection: Air discharge tube, low cost, suitable for low-voltage scenarios.

6、 Core steps for selection

Determine the protective voltage

Select the breakdown voltage (Vbr) based on the operating voltage (VCC) of the protected circuit, usually Vbr=1.5 × VCC.

Example: Choose 300V~470V gas discharge tube for 220V AC circuit.

Evaluate flow capacity

Select the flow capacity (Imax) based on the application scenario:

Power lightning protection: 10kA~100kA (industrial/communication).

Signal lightning protection: 1kA~5kA (consumer electronics).

Antenna feeder lightning protection: 10kA~100kA (base station/radar).

Match signal rate

High speed interfaces (such as RS-485 and CAN bus) require the selection of ultra-low capacitance models (<1pF).

Formula: The signal attenuation caused by capacitance Δ V=I × C × Δ t, ensuring that Δ V<5% × Vswing.

Thermal Design and Reliability

Calculate energy dissipation: E=Vclamp × Ipeak × tpulse, ensuring that it is lower than the rated energy absorption capacity of the gas discharge tube.

Choose certified models (such as UL, VDE, AEC-Q200).