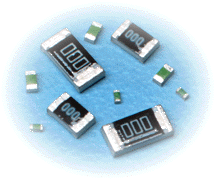

Thick film surface mount resistors are a key component widely used in electronic circuits. Their manufacturing process mainly involves screen printing and high-temperature sintering, and they have the characteristics of low cost and strong power tolerance. The following are the main categories and characteristic analysis of thick film surface mount resistors:

1、 Conventional series thick film surface mount resistors

Characteristics

Manufacturing process: A resistor paste mixed with ruthenium oxide and glass powder is used to form a resistor layer through screen printing and high-temperature sintering (about 850 ° C), with a thickness usually above 10 microns.

Accuracy and tolerance: The tolerance range is wide (± 1%~± 5%), suitable for scenarios with low precision requirements.

Temperature coefficient (TCR): TCR has a wide range (± 50~± 400 ppm/° C), and the resistance value changes significantly with temperature.

Power and Size: The power covers 1/20W to 1W, the size covers 0201 (0603 metric) to 2512 (6432 metric), and the maximum operating voltage can reach 200V.

Application: Low cost scenarios such as consumer electronics (such as power adapters, household appliances), industrial control, etc.

2、 High power thick film chip resistor

Characteristics

Power density: By optimizing electrode structure and substrate materials (such as high-purity alumina), higher power (such as 3W) can be achieved in smaller package sizes (such as 2512).

High temperature and pressure resistance: The working temperature range is 55 ℃ to+155 ℃, and some models can withstand a voltage of over 5000V.

Reliability: Passed AECQ200 certification, suitable for high reliability demand fields such as automotive electronics.

Applications: automotive electronics (such as current detection, voltage division), industrial power equipment, etc.

3、 High resistance thick film surface mount resistor

Characteristics

Resistance range: covering 100K Ω to 10T Ω, it is a high resistance category in thick film resistors.

High voltage resistance: The maximum working voltage can reach 6000V, suitable for high-voltage circuit protection.

Non magnetic design: Using PtAg electrode material to avoid interference with high magnetic field environments (such as MRI equipment).

Applications: Medical equipment (such as MRI, CT), aerospace instruments, petroleum exploration equipment, etc.

4、 Low resistance thick film surface mount resistor

Characteristics

Resistance range: as low as 0.5m Ω~22m Ω, suitable for high current detection.

Low inductance structure: The integrated design reduces parasitic inductance and improves high-frequency performance.

Heat dissipation capability: High thermal conductivity alloy material is used to reduce the heat dissipation pressure of the circuit board.

Applications: power management (such as chargers, UPS), electric vehicle battery protection, etc.

5、 Thick film surface mount resistors for automotive use

Characteristics

Environmental adaptability: sulfur resistant design, suitable for sulfur-containing environments; Passed AECQ200 certification, resistant to high temperature and high humidity.

High reliability: The multi-layer electrode structure enhances mechanical strength, and 100% CCD detection ensures quality.

Power and size optimization: Achieve 3W power in the 1225 package, balancing miniaturization and high load requirements.

Application: Automotive electronic systems (such as ECU, sensors, LED drivers).

6、 Thick film resistor array and network resistor

Characteristics

Integrated design: Multiple resistors are integrated into a single package (such as 4R8P, 2R4P) to save PCB space.

Diversified structure: Provides convex and concave electrodes, supports T-shaped or L-shaped network configurations.

Consistency and accuracy: The matching degree of resistance values within the same package is high, and the tolerance can be controlled within ± 1%.

Applications: digital circuits (such as signal voltage division), communication equipment, automation control systems.

7、 High precision thick film surface mount resistor

Characteristics

Precision improvement: By optimizing the slurry formula and process, the tolerance can reach ± 0.5%~± 0.1%.

Temperature stability: TCR as low as ± 25~± 50 ppm/° C, suitable for temperature drift sensitive scenarios.

Material improvement: Adopting metal glaze coating to enhance long-term stability and moisture resistance.

Applications: Medical instruments, precision measuring equipment, high-precision operational amplifiers.

Thick film surface mount resistors cover diverse needs from conventional consumer electronics to high-precision industrial fields through different materials, processes, and structural designs. Its core advantages lie in cost-effectiveness and power carrying capacity, while further expanding its application boundaries through technological innovation such as high resistance and low TCR design. Users can choose appropriate categories based on the accuracy, power, and environmental requirements of specific scenarios, and refer to manufacturer specifications (such as Yageo, Vishay, Lizhi, etc.) to obtain detailed parameters.