Analysis of the technical advantages and applications of Ellon EAM16FT3R00DES in sulfide resistant metal film patch resistors

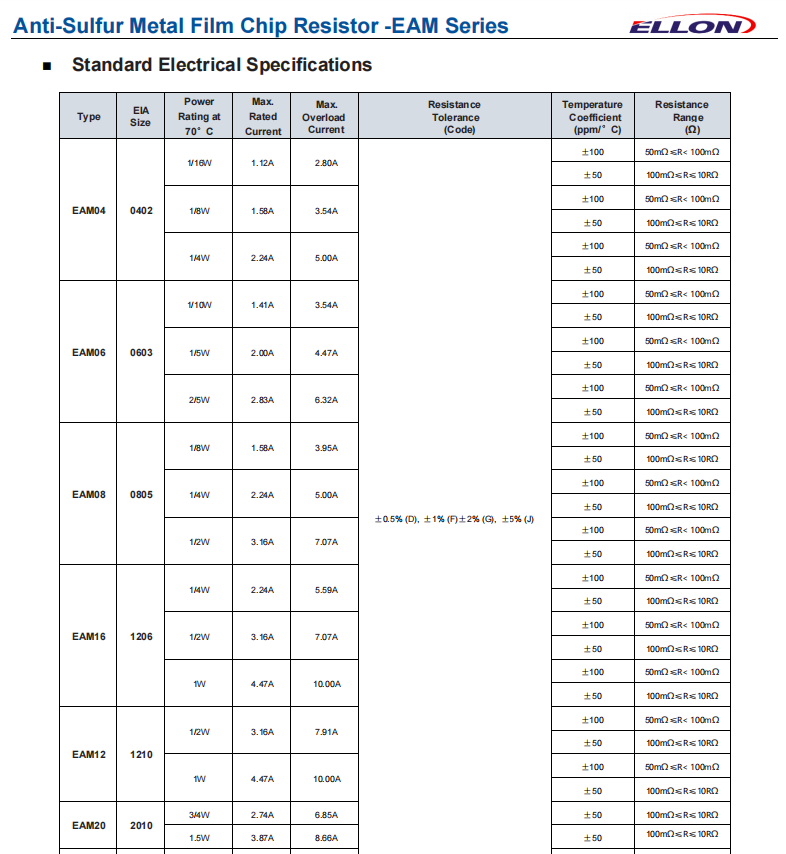

In the field of electronic components, sulfide resistant metal film patch resistors have become key components in industrial, automotive electronics, and communication equipment due to their stable performance in harsh environments. As a professional resistor manufacturer, Ellon's EAM16FT3R00DES resistor model has become the preferred solution for high reliability circuit design due to its 1206 package, 3R resistance value, ± 1% accuracy, 1W power, and ± 50PPM temperature drift coefficient. This article will delve into its technical characteristics and advantages in sulfur resistance.

1、 Core characteristics of sulfide resistant metal thin film resistors

The core value of sulfide resistant metal film surface mount resistors lies in their resistance to sulfide corrosion. In environments containing sulfur-containing gases such as H ₂ S and SO ₂, the silver electrode of a regular resistor is prone to react with sulfur to produce silver sulfide, leading to resistance drift or even circuit breakage. Ellon optimizes the material process by covering a special protective layer on the surface of the resistor to block the penetration of sulfur elements, ensuring the long-term stability of the resistor in chemical, mining, or humid and hot areas. Experimental data shows that its sulfur resistance meets the ASTM B809-95 standard, and its lifespan is more than three times longer than conventional products.

2、 Parameter Analysis of EAM16FT3R00DES

1206 package and 1W power

This model adopts a 1206 package (3.2mm × 1.6mm), achieving a rated power of 1W in a compact size, balancing heat dissipation requirements and space utilization, and is suitable for high-density PCB layouts.

3R resistance and ± 1% accuracy

The 3 Ω low resistance design can effectively reduce circuit losses, combined with a tolerance of ± 1%, meeting the accuracy requirements of precision current detection, power modules, and other scenarios.

± 50PPM temperature drift coefficient

Within the range of -55 ℃ to+155 ℃, the rate of change in resistance value is controlled at ± 50PPM/℃, which is significantly better than that of general thin film resistors (usually ± 100PPM), ensuring signal stability under wide temperature conditions.

3、 Typical application scenarios

Anti sulfide metal film patch resistors are particularly suitable for the following environments:

Automotive electronics: Engine control unit (ECU), LED headlight drive, resistant to sulfide corrosion released by fuel additives.

Industrial automation: frequency converters, PLC modules, suitable for high humidity and high pollution environments in factories.

Outdoor equipment: photovoltaic inverters, communication base station power supplies, to cope with temperature differences between day and night and atmospheric corrosion.

4、 Ellon's brand technology advantages

As a professional resistor manufacturer, Ellon strengthens its product competitiveness through three technologies:

Multi layer passivation process: A composite protective layer of SiO ₂ and epoxy resin is formed on the surface of the thin film resistor to enhance its resistance to vulcanization and moisture.

Laser resistance adjustment technology: using precision laser cutting to ensure ± 1% accuracy and batch consistency.

Fully automatic detection system: ensures factory reliability through 100% resistance testing and sampling vulcanization acceleration testing.

5、 Summary

Ellon EAM16FT3R00DES anti sulfide metal film surface mount resistor has solved the problem of circuit failure caused by sulfide corrosion through material innovation and process upgrading. The combination of its 1206 package, 3R resistance, and 1W power not only meets the trend of miniaturization design, but also provides guarantees for high reliability applications. In the context of Industry 4.0 and the rapid development of new energy vehicles, such high-performance resistors will become key components for improving equipment environmental adaptability.

By selecting Ellon anti sulfide metal film surface mount resistors, engineers can significantly reduce maintenance costs, extend equipment life cycles, and achieve dual optimization of safety and economy under harsh working conditions.