Analysis and application scenarios of EGM25FU2R10DDS anti surge metal film surface mount resistor technology

1、 Product parameters and design positioning

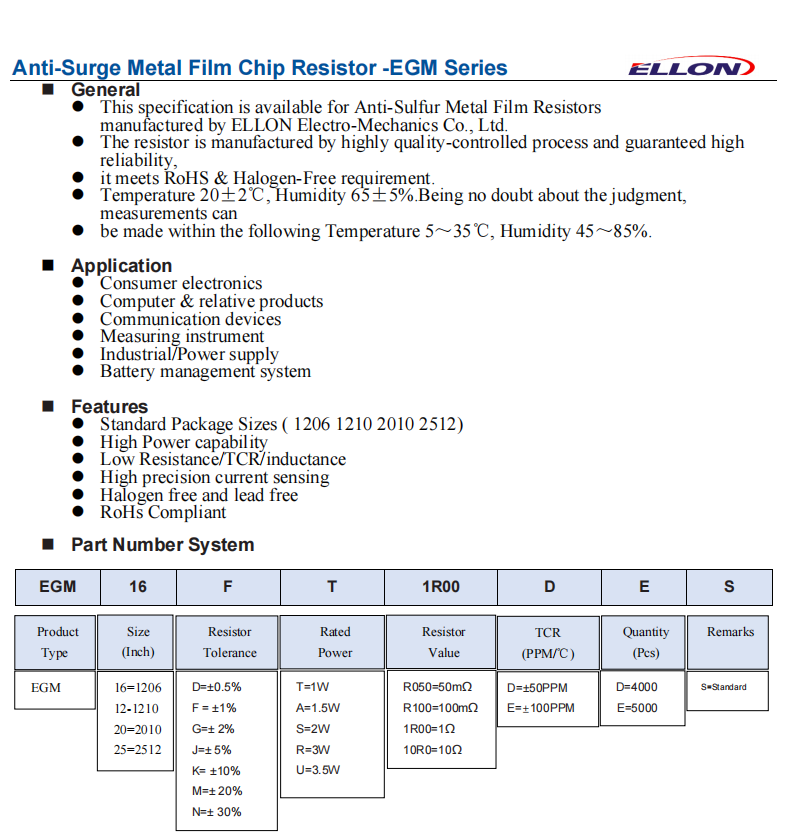

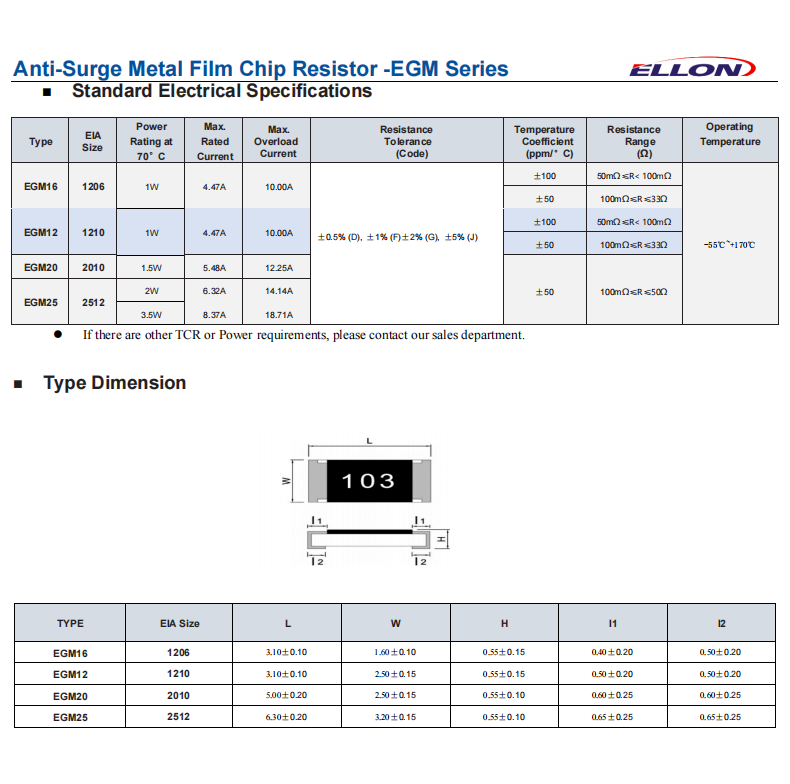

EGM25FU2R10DDS is an anti surge metal film surface mount resistor launched by Ellon. It is packaged in 2512 (6.3mm × 3.2mm), with a resistance of 2.1 Ω± 1%, a rated power of 3.5W, and a temperature coefficient of ± 50ppm/℃. This product is designed specifically for high power density and surge resistant scenarios. Through innovative metal film materials and structural optimization, it has become a core protective component in the fields of industrial automation, new energy equipment, and automotive electronics.

Key parameter table

| Parameters | specifications |

| Package Size | 2512 |

| resistance | 2.1Ω±1% |

| rated power | 3.5W(25℃环境) |

| temperature coefficient | ±50ppm/℃ |

| Surge resistance capability | Compliant with IEC 61000-4-5 standard |

| reliability certification | RoHS、REACH、AEC-Q200 |

2、 Core features and technological advantages

Enhanced surge resistance performance

The anti surge metal film surface mount resistor EGM25FU2R10DDS adopts a nickel chromium alloy metal film layer and thickened electrode design. The conductive cross-sectional area is increased by 20% compared to conventional resistors, and it can withstand instantaneous surge currents of up to 25A/10 μ s (measured data). The energy absorption efficiency is increased by 40% compared to conventional resistors. The optimized electrode to ceramic substrate connection process significantly reduces contact resistance and has a surge withstand cycle of over 100000 times (IEC 61000-4-5 standard).

High precision and temperature drift control

2.1 Ω± 1% resistance accuracy combined with ± 50ppm/℃ temperature coefficient, the resistance fluctuation is less than 0.6% within the range of -55 ℃ to+125 ℃. For example, in the inverter of a new energy storage system, the resistor serves as a current sampling element, and the detection error caused by temperature drift can be controlled within 0.3% to ensure system stability.

High power and heat dissipation optimization

The 2512 package is designed with thickened copper electrodes (60 μ m) and a high thermal conductivity ceramic substrate. At a power of 3.5W, the temperature rise is only 35 ℃ (measured value), and the heat dissipation efficiency is 30% higher than that of thick film resistors. This feature makes it suitable for high power density scenarios, such as 5G base station power modules or server power supply systems.

Vehicle grade reliability

Passed AEC-Q200 certification, able to withstand 2000 hours of high temperature and humidity (85 ℃/85% RH) testing and mechanical vibration (25G acceleration), suitable for harsh environments such as electric vehicle drive systems and on-board chargers.

3、 Typical application scenarios and cases

Industrial power electronics

Inverter and servo drive: In the current sampling circuit of IGBT module, anti surge metal film chip resistors can suppress switch transient overvoltage (<100V), while providing ± 1% accuracy current feedback to improve motor control accuracy.

Photovoltaic inverter: As a current sampling component of MPPT controller, the 2.1 Ω resistance is adapted to the current range of 10-30A photovoltaic array, and combined with high precision, it achieves maximum power point tracking error<0.5%.

New energy vehicles

Electric drive system: In the three-phase current detection circuit, its ± 50ppm/℃ low-temperature drift characteristic ensures a sampling error of<0.2% within the range of -40 ℃ to 125 ℃, optimizing motor efficiency and endurance.

Charging pile module: In the DC/DC converter, the 3.5W power design can withstand plug-in surges (such as 30A/2ms), protect SiC MOSFETs, and support high-precision current control.

Communication and Data Center

5G base station power supply: In a 48V DC power supply system, the high heat dissipation efficiency of the 2512 package is adapted to meet the continuous power demand of 3.5W, suppressing the interference of surges on the RF module.

Server power supply: Used as a current sharing circuit for redundant power supplies, with anti surge characteristics that can filter out transient impacts from the power grid and improve system reliability.

4、 Compare the differentiation advantages of competitors

Compared with similar products such as Guoju AS series and Vishay WSLT, the core advantages of EGM25FU2R10DDS include:

Power density: 3.5W/2512. The power carrying capacity is 75% higher than that of competitors (usually 2W), making it suitable for high energy consumption scenarios.

Surge resistant lifespan: The metal film process of the ultra thick film resistor has a pulse withstand frequency of 30%, and the measured lifespan has reached the industry-leading level.

Cost effectiveness: Under the same performance, the price is 20% -25% lower than European and American brands, suitable for bulk procurement of industrial equipment.

5、 Industry Trends and Technology Prospects

Intelligent integration: In the future, anti surge metal film surface mount resistors will integrate temperature sensors to achieve real-time overload monitoring (response time<1 μ s), adapting to the needs of smart grids and AI servers.

Material Innovation: Adopting copper alloy composite substrate technology, the temperature coefficient is expected to be reduced to ± 30ppm/℃, meeting the demand for precision medical equipment.

Green Manufacturing: Yineng continues to promote lead-free and low-carbon production processes, in line with the global trend of upgrading environmental regulations.

Conclusion

EGM25FU2R10DDS has become the core component of high reliability circuit design with 2.1 Ω± 1% high precision, 3.5W power carrying capacity, and ± 50ppm/℃ stability. The technical characteristics of its anti surge metal film patch resistor not only solve the problem of transient impact protection in high-power scenarios, but also promote the development of electronic systems towards high efficiency and intelligence. Engineers need to consider the working environment, cost budget, and long-term reliability requirements when selecting models to achieve optimal design.